Revision [767]

This is an old revision of W123FrontShocks made by WebMaster on 2011-03-11 15:39:39.

Front Shock Replacement

on the 1982 300CD (W123.153)

by JHZR2

03/19/11

W123 Front Shock Replacement DIY

Having just done tie rods, idler arm, brake lines, oil separator seal and idler arm rebuild on my 82 300CD, I have a lot of pictures to show and DIYs to put together. The tie rod/idler one has a LOT of images, so Im going to work that one last. First one is shocks... Here it goes:

My shocks at 163k still had OK bounce, but were showing some rub marks, surface rust and some leakage that I guess is lubricating oil from inside. I have front and rear shocks, so I figured I'd start working the replacements. I did the fronts this time, and will do the rears when I have the seats out for window regulator replacement.

Tools Required:

- Plier or adjustable wrench

- Box end wrenches (17mm), a ratcheting box-end is helpful

- Ratchet w/17mm socket

- 10mm 12 point socket

- 3" extension

I replaced the shocks on my 83 with the wheels on the ground. I replaced the shocks on my 82 with the wheels in the air because I already had the car up. It is slightly easier to have the wheels in the air.

The first thing to do is remove the locknut system that is on top of the shock rod. This could be one of two setups, either a nut with another nut locking it down, or a single locking nut. This will require either: a wrench to hold the first with a second wrench or socket to undo the top one in the case of two nuts; or else if there is just a single locknut on the shaft, then a wrench and a plier or adjustable to actually hold the shaft. In the case of two nuts, then the second nut is removed by the process mentioned with the locknut case.

My wheels were straight ahead the whole time. Some suggest that it is easier to move the wheels either way for access. I do not see the need. The next step is to remove the accessible bolts that hold the shocks to the lower control arm. These are the outboard bolts. I used a standard 12 point socket from a ratchet set.

After they are removed, get the shaft pushed down through the hole in the fender from above (I found a long 1/4" ratchet extension helped) and muscle the shock shaft down by pushing via the boot.

You can get the shaft to stay down by releasing it against the fender liner. Angle it so that the inboard 10mm bolts are accessible.

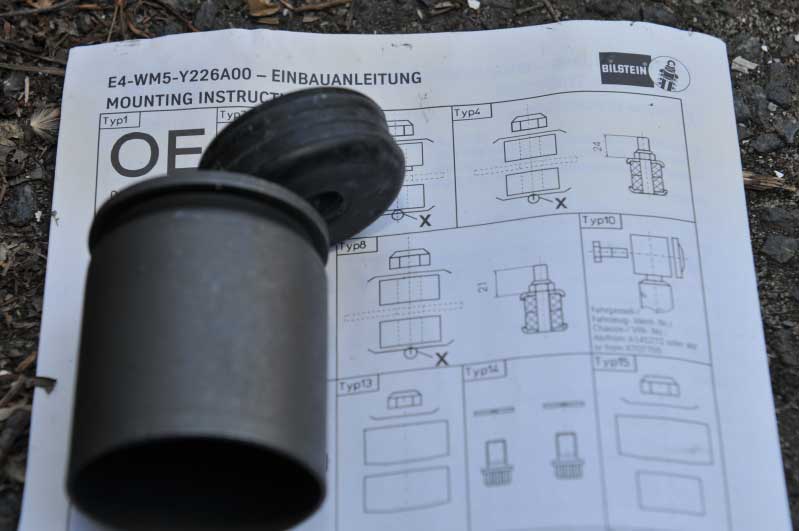

Now, the confusing part. There is at least one thread that I wrote from long ago and continued when I did these installs pertaining to how to properly set up the new boots, washers, etc. The shock is supposed to have a "type" marking on it, but mine didnt.

Key is to remove the black metal part from inside the new boot.

One of the two supplied black rubber buffers sits on the beveled washer part that makes the top of this item.

Another view:

So slide the rubber part in and then put the black metal item back into the boot. Make sure it is all seated properly. Slide this along the shaft until it bottoms at the small washer on the shaft.

Installation really is the reverse of removal. Compress the shock a bit, and let it jam into the plastic liner of the fender. Align it so that the inner bolt hole is exposed first, and get it threaded in. I also hand-threaded the outer bolt just a bit by hand to make sure that everything is well-aligned. Tighten the inner bolt down first.

Then release the shaft into the hole and go ahead and tighten the second bolt.

The new shocks likely have a locknut, so the tools are the wrench and the adjustable wrench or plier. The key is to hold the small tab on the top of the shock shaft so it does not spin, and then tighten down the locknut.

I tightened it so that three threads on the shock shaft are visible.

Done!

Discuss this DIY here.

-JHZR2

CategoryDiy